Nebraska U breaks ground on Feedlot Innovation Center

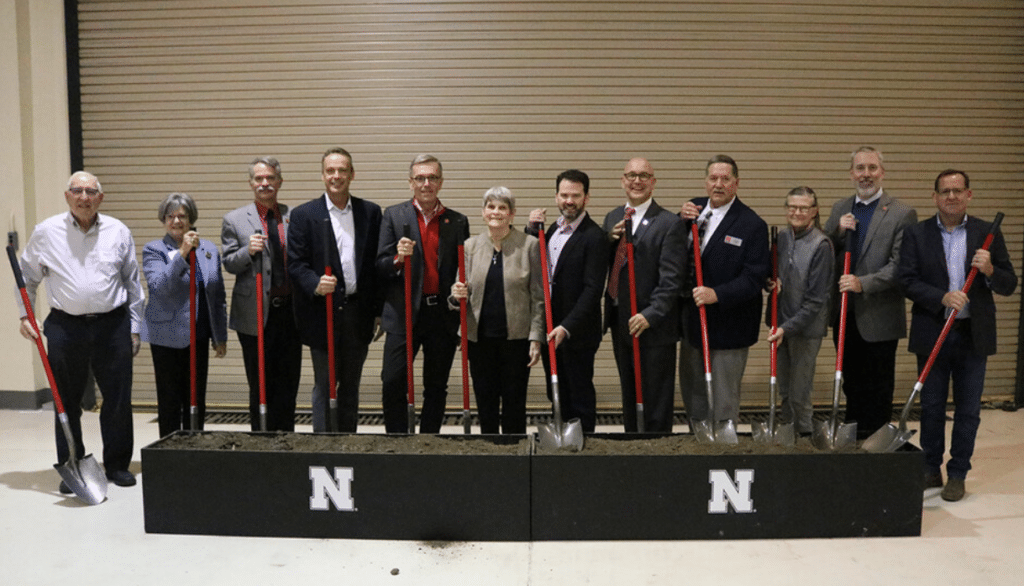

More than 150 leaders from across Nebraska’s beef industry gathered at the University of Nebraska–Lincoln’s Eastern Nebraska Research, Extension and Education Center near Mead Nov. 4 to celebrate the groundbreaking of the Feedlot Innovation Center.

The $7.2 million facility will pave the way for world-class research projects and teaching and extension opportunities in a commercial-scale, state-of-the-art feedlot. In addition, the facility will serve as a one-of-a-kind testbed where industry partners can see how new and emerging technologies work.

It will officially be named the Klosterman Feedlot Innovation Center, pending approval of the University of Nebraska Board of Regents. The name honors John and Beth Klosterman of David City, who are longtime supporters of both the university and its Institute of Agriculture and Natural Resources.

The new center will be “a very unique facility in terms of the types of research we can do,” said Doug Zalesky, director of the extension center.

Construction of the facility marks the next step in a long history of beef innovation at Nebraska, Zalesky said. The extension center, which is celebrating its 60th anniversary this year, built its first feedlot pens in 1964. The next year, the university hired Terry Klopfenstein, who went on to become the longtime leader of the university’s ruminant nutrition program and was a pioneer in using byproducts from the ethanol and sweetener industries to supplement cattle feeding. Beef research remains central to the extension center’s programming.

The Feedlot Innovation Center will include a complex with two cattle comfort and research buildings, a feed technology facility, innovative open lots and an animal handling facility.

Settje Agri-Services and Engineering

The Feedlot Innovation Center will include a complex with cattle comfort and research buildings, a feed technology facility, innovative open lots and an animal handling facility.

The Feedlot Innovation Center will include commercial-scale open air and covered pens, allowing researchers to improve cattle performance and environmental impact in varied settings. It will also include a 240-head feeding facility that will allow researchers to use precision techniques to study the outcomes of various feeding protocols, measure emissions and study the various uses for precision feeding technology already on the market. The center will allow for expanded research of the impact of low-stress animal handling and increased emphasis on animal welfare. A new cattle handling facility and enclosed classroom will give students hands-on experience and allow for training opportunities for Nebraska’s beef industry workforce.

“This is being built with all the right things in mind,” Chancellor Ronnie Green said.

The facility will also serve as an innovation laboratory, which industry partners, ag-tech startups, producers and others can use as a proving ground for new products, said Mike Boehm, Harlan Vice Chancellor for IANR and NU vice president.

Researchers across IANR are committed to ensuring that important discoveries can move quickly from lab to field, or in this case, feedlot, Boehm said. This is important in Nebraska, which has about 720 cattle feeders with 1,000 head or more.

“This innovation center is the next step in that,” he said. “It allows us to bring together public and private partnerships in ways that push the envelope.”

The new center will also be a key component of the university’s Beef Innovation Hub, which aims to advance, support and communicate continuous improvement of beef production, economic vitality and natural resources stewardship through innovative research, education and extension.

Fundraising for the project is ongoing. Major donors include John and Beth Klosterman; JBS USA; Greater Omaha Packing; Farm Credit Services of America; Dennis and Glenda Boesiger; and the Klopfenstein Fund, which includes gifts from a number of alumni, colleagues and industry partners who knew and worked with Terry Klopfenstein. In addition, Daniels Manufacturing, FBI Buildings Rock Solid Concrete and others have made significant in-kind contributions.